Documentation Writing

Professional SOP’s (Standard Operating Procedures) and Documentation Writing

Professional SOP’s (Standard Operating Procedures) and Documentation Writing

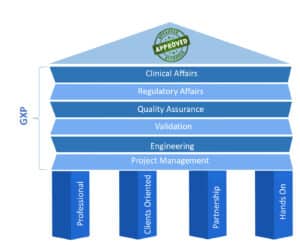

Every successful task starts with planning and documenting the procedures that should be carried out. Working according to procedures not only prevents mistakes, but it also creates order, clarity, and assists in viewing the complete picture and its details. Moreover, documenting these procedures make it easier to go back and check “what went wrong”, add new procedures in future developments and provide a good basis for QA, validations, and product-related documentation. We at RS NESS always work according to accurate procedures and are experts in creating them.

Before writing the procedures or SOP’s, there are several important points to be taken into consideration: We at RS NESS are investing considerable resources in understanding our customer’s organizational policies, tasks, and internal behavior, while understanding and focusing on the type of procedures and their target, according to the requirements of the customer and the GMP rules.

Writing operating instructions for equipment and systems

The operating procedures are accurate written instructions that detail step by step the activity, the results, and the safety and work instructions. The procedures relating to the proper way in which the machines & systems should be operated, maintained, and the tasks performed, efficiently and safely, including preventive maintenance, calibration procedures, and relevant forms.

Operating procedures

The work procedures define the correct work process for the employee. The procedures are clear, precise, practical and relevant to the target audience. Their importance lies in creating a uniform and meticulous standard, which allows a proper process of the actions, safety, and responsibility during the work.

Calibration procedures

A calibration procedure defines the actions required to ensure the quality, reliability, and accuracy of the measurement tools or instruments in the organization.

Writing maintenance policies processes and procedures

The maintenance policy defines the approach and actions of the department, including among the rest:

- Planning and scheduling of maintenance operations

- Work methods

- Computerized maintenance management system

- Equipment records

- Inventory management of spare parts

and more

Maintenance instructions for equipment and systems – detailing and documenting the periodic operations that should be performed when handling the equipment or system, that were defined by the equipment supplier, or that rely on the customer’s experience and his approach to the maintenance of the equipment.

Professional SOP’s (Standard Operating Procedures) and Documentation Writing

Professional SOP’s (Standard Operating Procedures) and Documentation Writing