Process

Project Scope – Plant breeding Farm

Process

➢ HVAC design and installation

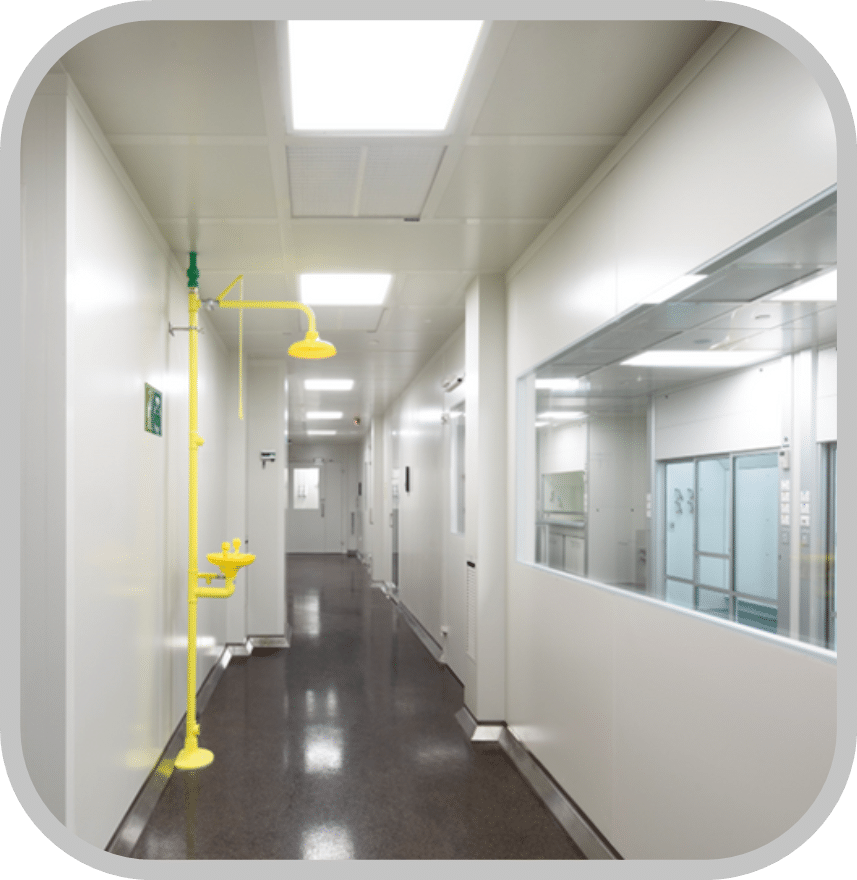

➢ Facility (Clean rooms modification for new design)

The Facility is designed to meet all aspects of IMC-GMP, EU-GMP, IMC-GAP and GACP and safety requirements.

➢ HVAC changes

➢ Facility (Clean rooms modification for new design)

➢ WFI system (New user points)

➢ CIP system

➢ Cooling and heating system

➢ HVAC changes

➢ Facility (Clean rooms modification for new design)

➢ Purified Water (New user points) , compressed air , nitrogen , electricity , breathing air, industrial steam.

➢ Cooling and heating system

Research for RoHS-3 compliant replacement (glue)

Update BoM

Test components in TUV laboratory

Certifying all components of pumps

Certifying process of assembling

Certifying suppliers as RoHS-3 compliant supplier

Update/ create technical file