How medtech giant BD uses R.S NESS Group to meet global regulatory standards at infusion pump plant

Israel-based Caesarea Medical Electronics, a global infusion pump systems manufacturer, was acquired by global medical technology giant BD (Becton, Dickinson and Company) (NYSE: BDX) in 2017. The move expanded BD’s infusion portfolio to include ambulatory, home and specialty care infusion pumps, with CME continuing to design, manufacture and market a range of infusion and syringe pumps, as well as related accessories and disposable administration sets for both home care and hospital settings. The Caesarea-manufactured infusion pumps are known for their compact and highly portable design, making them ideal for specialty applications such as IV and epidural anesthesia, pain management, and hospital (and home) nutrition. BD’s Caesarea plant started working with R.S NESS Group to build and implement the processes they needed to comply with global standards – and ended up discovering that those processes resulted not just in higher-quality products, but also in improved production capacity and customer satisfaction as well as 30% higher profitability.

The problem: Regulatory and quality gaps that needed to be closed fast

The acquisition of Caesarea Medical Electronics advanced BD’s mission to provide efficient end-to-end IV safety solutions – while at the same time giving CME an opportunity to close some significant regulatory, quality management, validation and engineering gaps. It was critical to close those gaps in order to ensure the pump manufacturer was meeting the standards of one of the largest medical technology companies in the world, with more than 70,000 employees around the globe.“We had to work very, very fast to build a plan to close all the gaps we saw in the plant,” said Idan Laifer, the BD plant manager responsible for the Caesarea pump plant. “We realized we couldn’t do it on our own, so we looked for a company that could help us make the change.”After speaking to several companies, BD selected R.S NESS Group to lead the ambitious project “because of its combination of knowledge and professionalism,” said Laifer.

“We were looking not only for a consultancy that could lead the way in facilitating compliance with global regulatory and quality standards, but also for a partner that could become an integral, embedded part of the factory to fully actualize the plan – and we found that in R.S NESS Group”

The solution: Overhauling all production processes to meet global standards

BD worked closely with R.S NESS Group to ensure the infusion pumps that the Caesarea plant manufactures are of consistently and reliably high quality and that all production processes meet global regulatory and quality management standards. To accomplish those objectives, they built and implemented a validation master plan (VMP) that revamped all production processes. It was a massive undertaking.

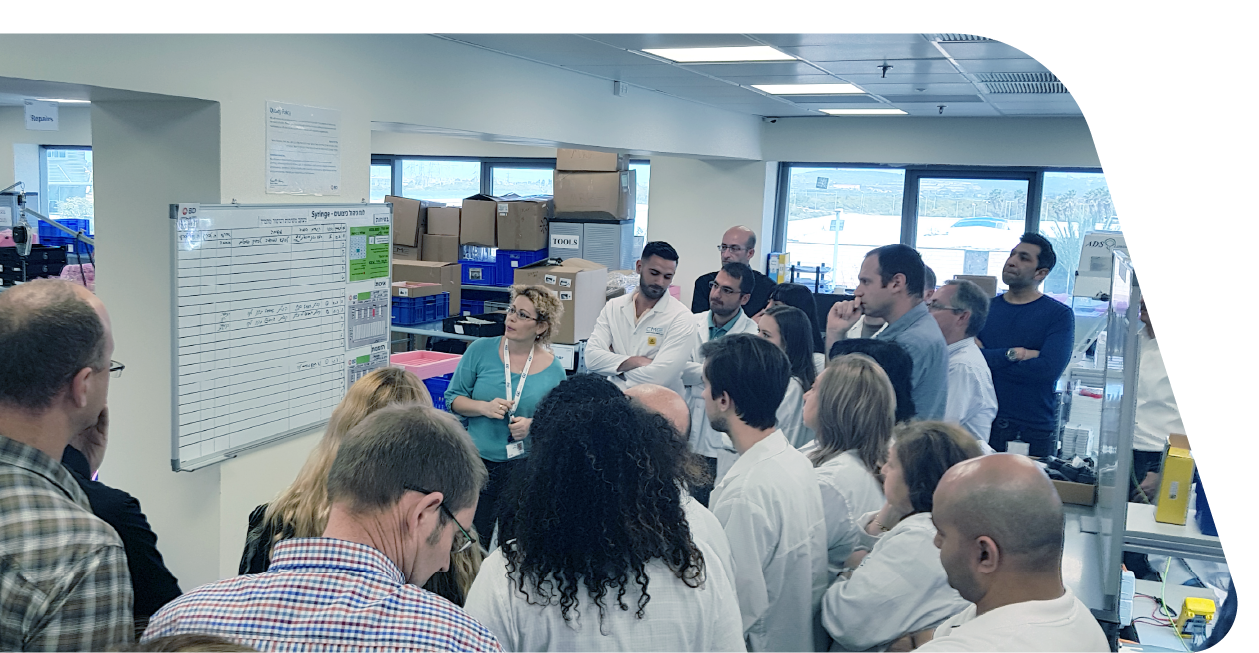

“We needed to overhaul all the regulatory and quality management processes for production,” said Laifer. “Everything that went into the QMS [quality management system] needed to be rebuilt. We had to destroy what was there in order to rebuild.”The overhaul included validating thousands of production processes across every stage of the manufacturing process, from raw material to components – including parts manufactured on-site using CNC machines – to final products. It also involved preparing, conducting and validating interim audits to check issues like the product dimensions and functionality of components and final products. The revamp took place in stages over two to three years, and at various points involved one to two dozen R.S NESS Group engineers embedded in the Caesarea plant and working closely with staff there to plan and implement the changes.

“We didn’t feel any difference between who works at R.S NESS Group and who works at BD,” said Laifer. “It was collaborative work.”

R.S NESS Group team leads for the regulatory, quality management, validation and engineering processes were also on-site to manage each vertical, and the joint teams worked with global BD personnel to improve quality management processes in preparation for internal and external audits. “R.S NESS Group took their knowledge into the plant to train the staff there – to dive into a system that was changing from moment to moment,” said Laifer.

BD also partnered with R.S NESS Group to upgrade its purchasing process, by implementing consistent standards for determining which suppliers to work with and consistent practices guiding the company on how to work with suppliers.

Other joint projects include ensuring that all devices involving electronics comply with new regulations, embedding the new generation of infusion pumps into the production process, upgrading the production maintenance system, and improving engineering and project management processes.

R.S NESS Group team leads for the regulatory, quality management, validation and engineering processes were also on-site to manage each vertical, and the joint teams worked with global BD personnel to improve quality management processes in preparation for internal and external audits. “R.S NESS Group took their knowledge into the plant to train the staff there – to dive into a system that was changing from moment to moment,” said Laifer.

BD also partnered with R.S NESS Group to upgrade its purchasing process, by implementing consistent standards for determining which suppliers to work with and consistent practices guiding the company on how to work with suppliers.

Other joint projects include ensuring that all devices involving electronics comply with new regulations, embedding the new generation of infusion pumps into the production process, upgrading the production maintenance system, and improving engineering and project management processes.

The impact: Boost gross margin over 30% in 2 years

The reason BD’s Caesarea plant started working with R.S NESS Group may have been to implement the processes they needed to comply with global standards – but ultimately they discovered that those processes had a very welcome side effect: increased profitability. What CME found was that better processes were the starting point of a virtuous cycle. Putting the right processes in place led to higher standards of quality, and those higher standards in turn made it easier to pass audits, reduced production problems and boosted capacity, improved product quality and customer satisfaction, and ultimately increased the profit margin. 30% higher profitability Perhaps the clearest indication of the ROI of stable and repeatable production processes is that the profitability of the pumps and other products manufactured by the Caesarea plant increased as a result of those processes – without the company needing to hire more employees or raise prices. Gross margin increased over 30 percent in two years as the cost per unit dropped. Profitability increased because the plant was able to manufacture more with the same number of people once they didn’t need to put as much time and effort into reacting to quality complaints from customers or fixing problems that got cited in audits or arose on the production line.“When you don’t need to put as many resources into reacting to complaints, you can do more,” said Laifer. “With fewer problems on the production line, our capacity rose and we were able to manufacture more products with the same number of people, so we became more competitive.”

Passing audits more easily

“Over the years, we performed better and better at quality audits of the factory conducted by regulatory bodies,” said Laifer.That applies even to major audits like the Medical Device Single Audit Program (MDSAP), which satisfies the regulatory requirements of Australia, Brazil, Canada, Japan and the United States.

“We started with a pretty high number of findings that had to be corrected – and we just completed an MDSAP audit a few weeks ago with no findings,” said Laifer. “As soon as there are processes in place, you raise the standards.”And passing audits faster means more resources can be allocated to production and sales, without losing time or momentum in a given market due to having to correct a slew of problems found in the audit.

Fewer production problems, greater capacity

Fewer production problems, greater capacity

Sometimes an overemphasis on process gets a bad rap, because badly implemented processes can seem like they do nothing but add a layer of bureaucracy or force people to check items off a list.

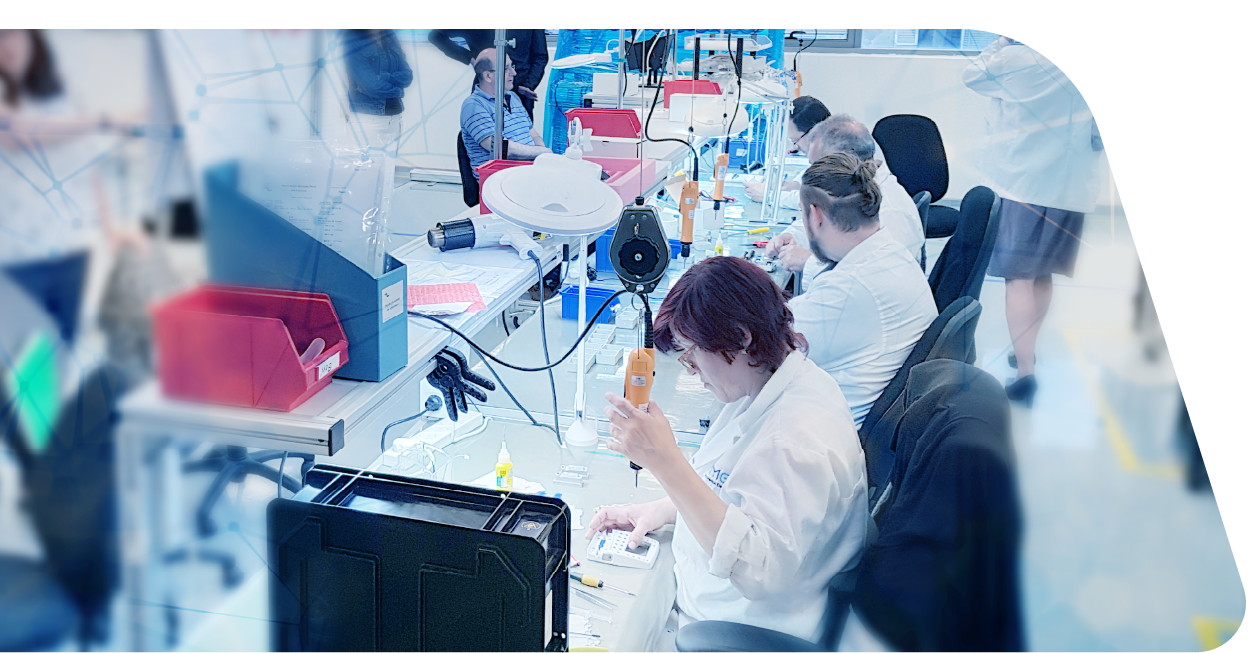

But a good production process can mean the difference between a plant that’s regularly halting production to deal with problems on the factory floor and one that can keep its focus on manufacturing products. It can affect how often production problems arise, how efficient the manufacturing process is, and how much can be produced on a day-to-day basis. “The validation proves that each production line and every stage of the manufacturing process is up to standards, and is stable and repeatable,” said Laifer. “This has led to fewer problems on the production line, which means our capacity has increased.”

High-quality products, more satisfied customers

High-quality products, more satisfied customers

In addition to improving the Caesarea plant’s ability to pass audits quickly and increase production capacity, better production processes also improved the quality and consistency of the infusion pumps being produced – and that significantly reduced the number of customer complaints.

“In the first one or two years, we wasted a lot of time and energy reacting to complaints,” said Laifer. “Now we barely get any customer complaints. Our customers are more satisfied.” “The pumps got better,” he said. “Customers know it will work.” Now that BD’s Caesarea pump manufacturer has worked with R.S NESS to build and implement a validated production process across its production lines, it is better able to keep its focus on manufacturing high-quality products rather than putting out fires. And that pays dividends – in customer satisfaction and revenue.